Our in-house team begins manufacturing key components such as the required mechanical equipment for the specific project.

Quality control checks are performed at each phase to ensure every component meets our rigorous standards. This gives us control over quality and the flexibility to customize according to project needs.

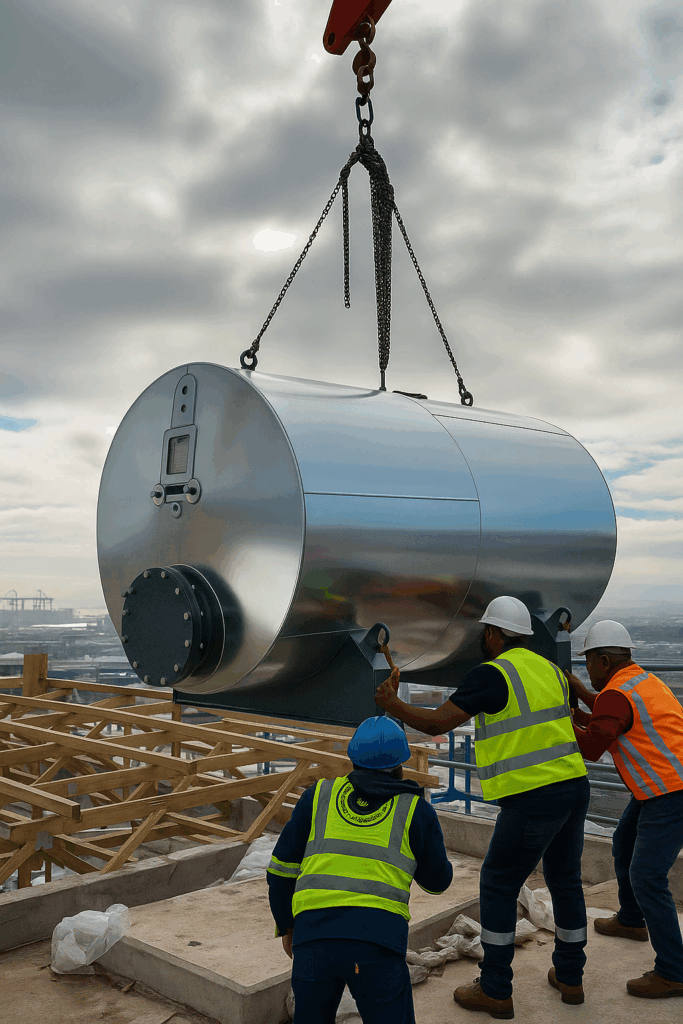

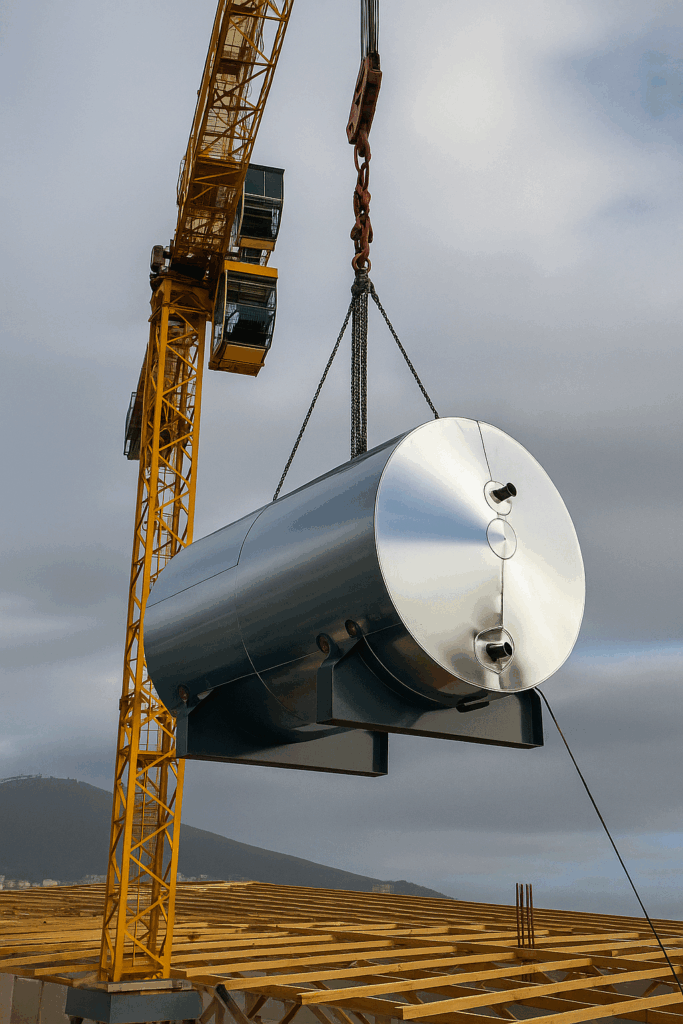

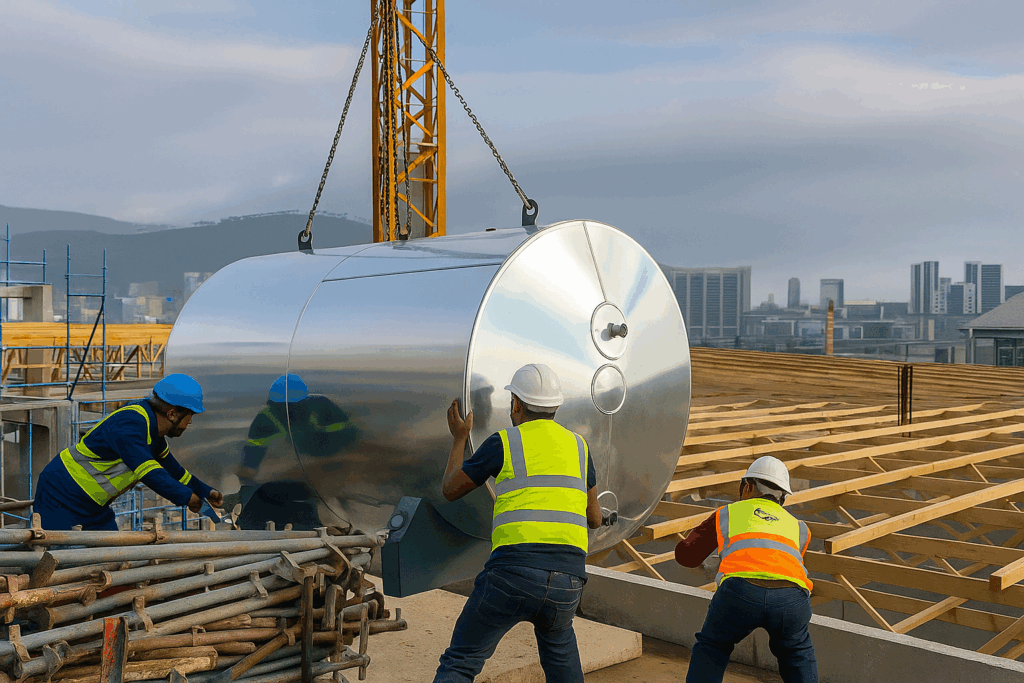

This is where the real on-site action begins. Our technicians and site crew mobilize to perform the mechanical installation, starting with unloading and placing large equipment using cranes and rigging gear. Every move is calculated – from positioning vessels into mechanical plant rooms to routing insulated piping and connecting electrical controls.

On any given day, our team is:

At Greenbro, the magic doesn’t just happen in the factory or the boardroom – it comes to life on-site, where our dedicated teams roll up their sleeves and get to work delivering complex mechanical solutions with precision, speed, and safety.

Every successful mechanical installation begins long before the equipment arrives on site. From careful project planning and supplier coordination to logistics and health and safety protocols, a full mechanical supply and installation project requires discipline, teamwork, and meticulous attention to detail. Here’s a glimpse into the day-to-day action that keeps Greenbro at the forefront of the industry.

Every Greenbro project starts with in-depth planning and collaboration. Site visits, technical assessments, and coordination meetings with the main contractor, engineers, and plumbing teams ensure that everyone is aligned with the scope of work and timelines. We work closely with partners to define clear expectations and ensure compliance with local regulations and SANS standards.

Once the equipment is manufactured and tested, the next challenge is logistics. Transporting large mechanical equipment, like heat pumps and vessels, requires precision planning, especially when lifting or craning is required on-site. Our team arranges secure transport, coordinates with rigging professionals, and ensures that all equipment arrives on-site safely and on time.

Once installation is complete, the systems are rigorously tested. We perform pressure tests, temperature performance evaluations, and energy efficiency checks to ensure the system is running optimally before handover. Our commissioning team remains on-site to support integration into the building’s operational systems and to train the client’s maintenance teams if required.

Our relationship with our clients doesn’t end once the installation is complete. We believe that reliable equipment must be matched with reliable service. That’s why we offer full after-sales support, including:

Scheduled preventive maintenance, helping to extend equipment lifespan and maintain energy efficiency.

Responsive breakdown support, with our technicians trained and ready to respond to faults quickly and effectively.

Performance tracking and adjustments, ensuring your system runs optimally as usage conditions evolve.

Spare parts availability, thanks to our in-house manufacturing and inventory system.

Greenbro’s ongoing commitment means our clients enjoy peace of mind, knowing they have a dependable partner for the long run.

We’re excited to continue showcasing the work happening on the ground. Keep an eye on our social media and blog for more behind-the-scenes updates, showcasing the people and the projects that power our success.

Date: 29/08/2025

Published by Karen Potgieter | Greenbro South Africa (Pty) Ltd